Glashütte (Ernst Kreißig) Watchmakers' LatheGlashütte Watchmakers' Lathe Page 2

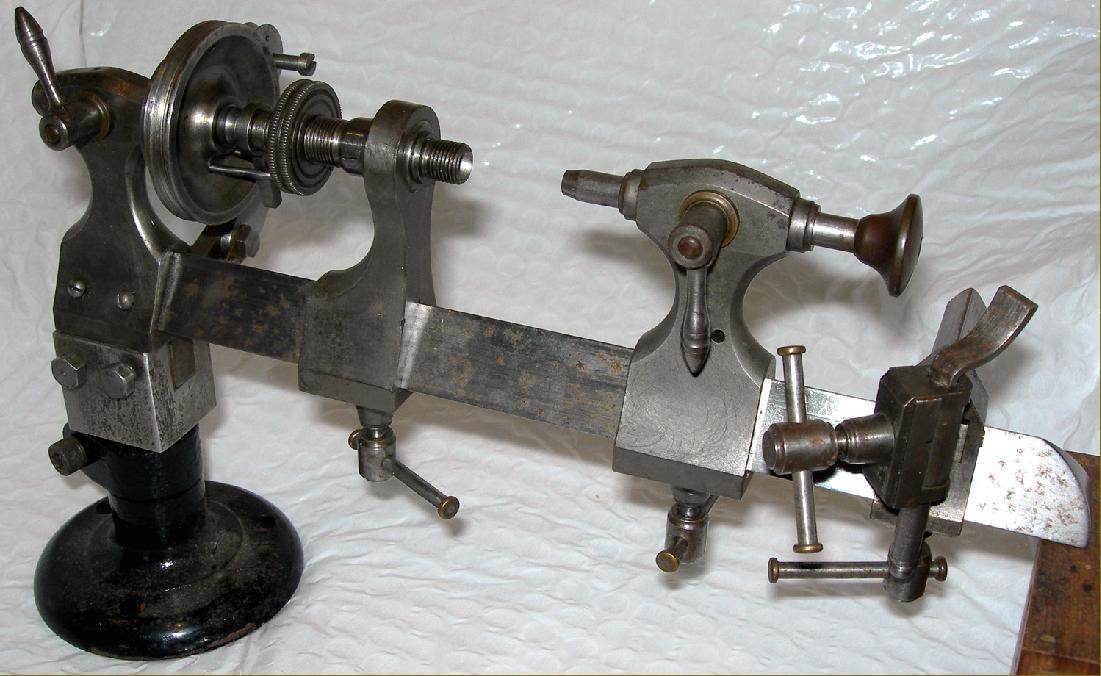

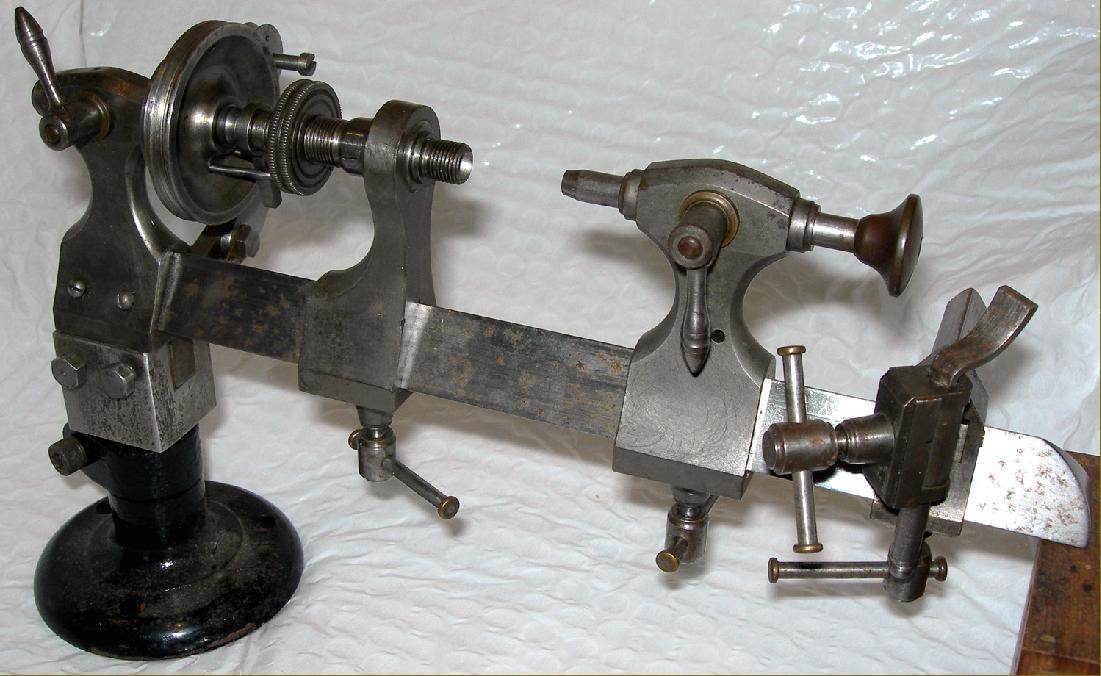

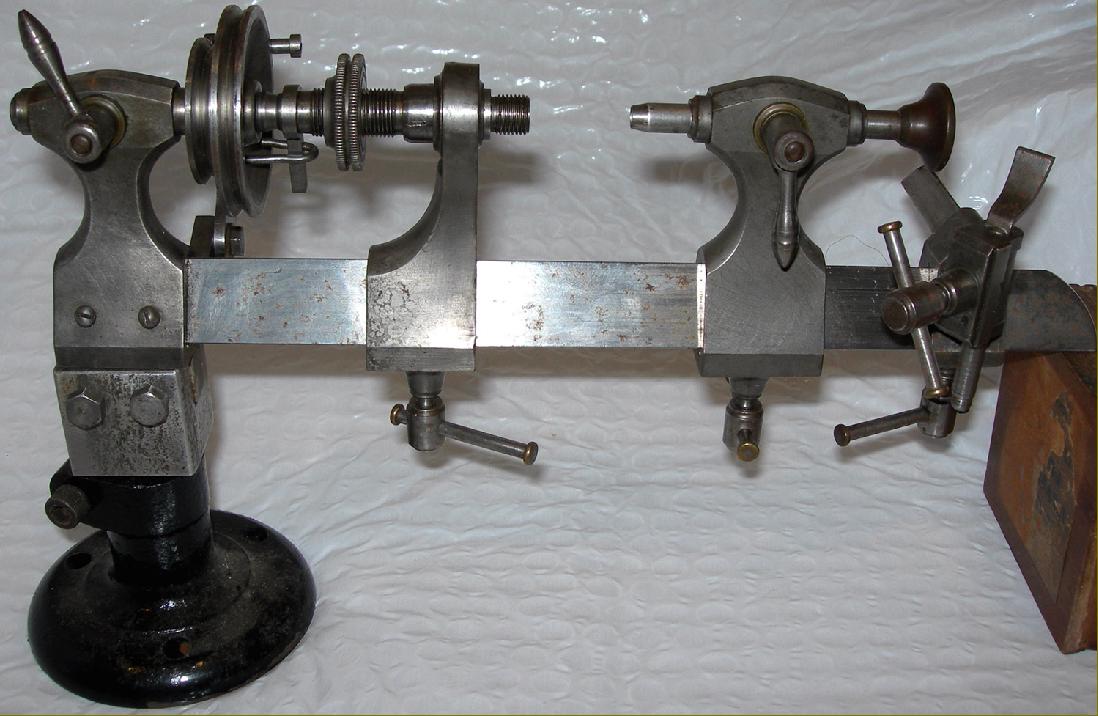

Of fine design and particularly beautiful execution the triangular-bed Glashütte lathe was manufactured in the 1800s by Ernst Kreißig, a maker of watchmakers' tools from the Glashütte area near Dresden. Glashütte was not only the German centre of high-class watchmaking (and a watch-makers' school) but also home to several machine-tool builders including Karl Renner. Although Kreißig offered several versions of his lathe his later models were more conventional in appearance, resembling those from Lorch and Boley. After WW2 Kreißig was trapped inside the Russian-occupied zone and, machines from the West needing hard-to-obtain D.Marks, most of the company's output was destined for local consumption.

Although the triangular bed might be considered a trade mark signature for many makes of precision lathe from the late 1700s to the late 1800s - the most famous being Henry Maudsley's revolutionary screwcutting lathe of around 1800 - its use also extended to small lathes for watch and clock work with the original machines produced by the well-known Gustav Boley (G.Boley) being of this pattern.

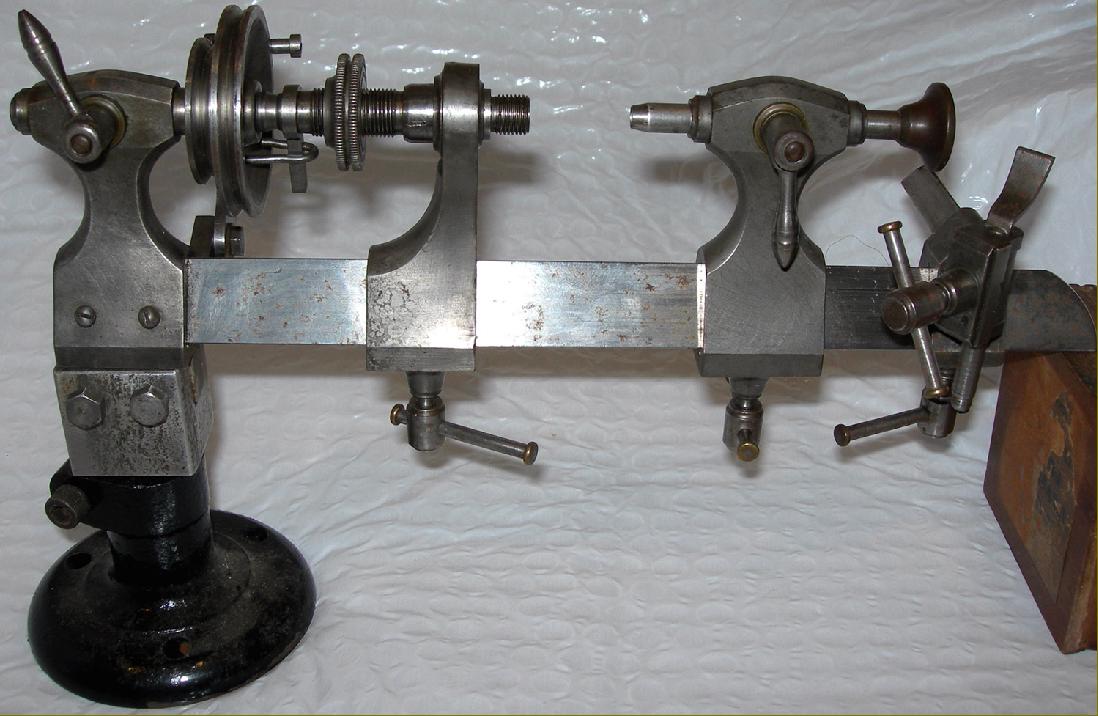

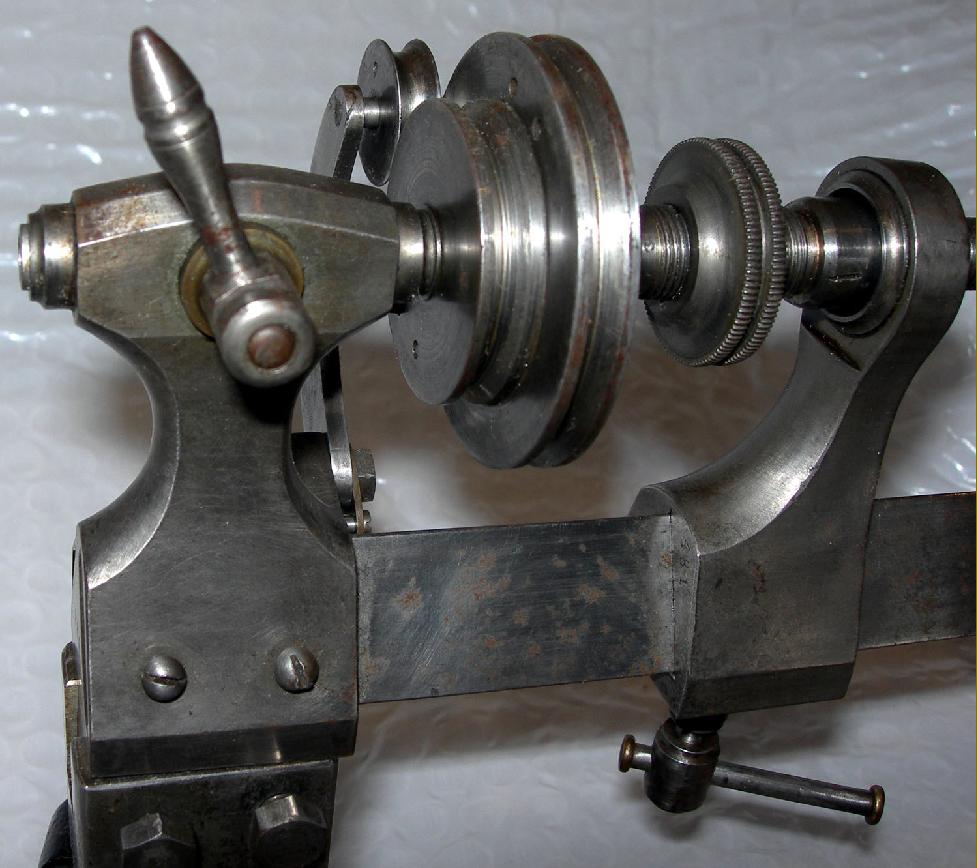

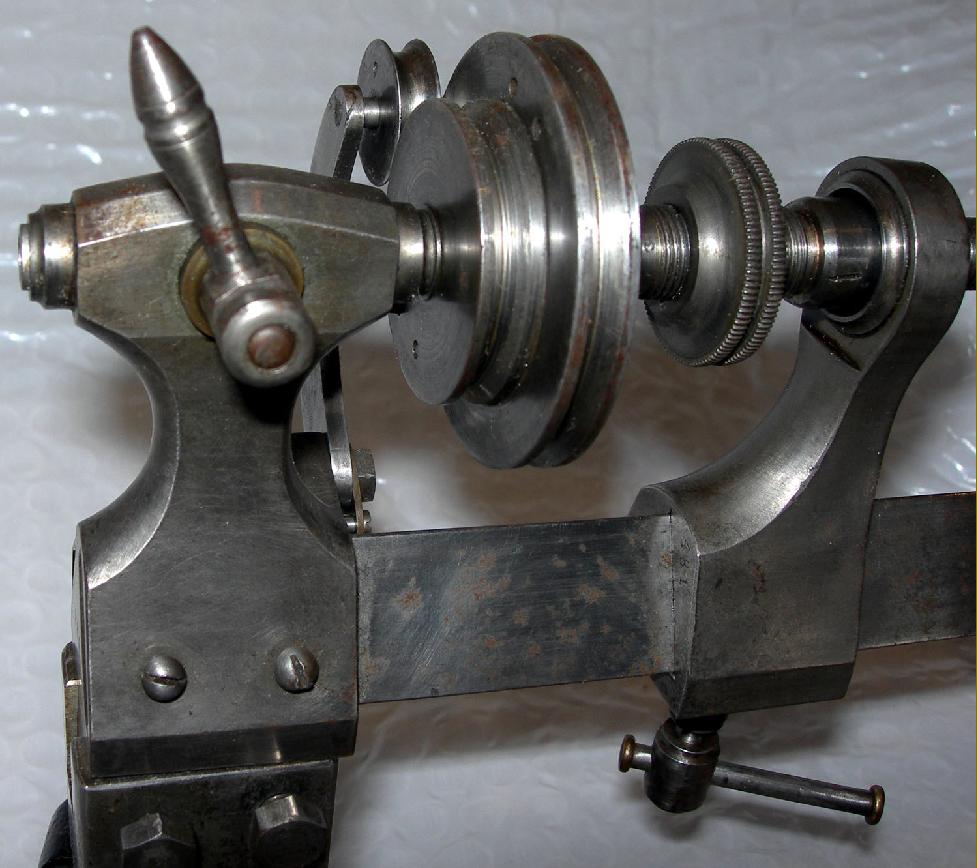

Because draw-in collets retained by a threaded tube passing up a hollow headstock spindle had yet to be invented - that was a development first incorporated in the American Webster Whitcomb lathe of 1888/9 - the headstock of the Glashütte had to be designed in an ingenious way. This was accomplished by separating it into two sections with that on the left (its shape strongly reminiscent of watchmaker's "turns") supporting a 2-step pulley with the drive transmitted, through a pin and dog, to a spindle supported in the other, right-hand element. This arrangement left a length of spindle exposed along its middle section through which was cut a slot, matching one also broached through each collet's solid 5.3 mm diameter stem. To lock a collet in place a long key was passed through the slots - leaving its ends protruding from each side of the spindle - and a knurled-edge ring screwed backwards against it. Although this assembly performed perfectly it required advanced standards of engineering craftsmanship to work accurately - craftsmanship that - without the aid of yet-to-be-invented shaping, planning or grinding machines - would have involved the finest of hand-fitting skills.

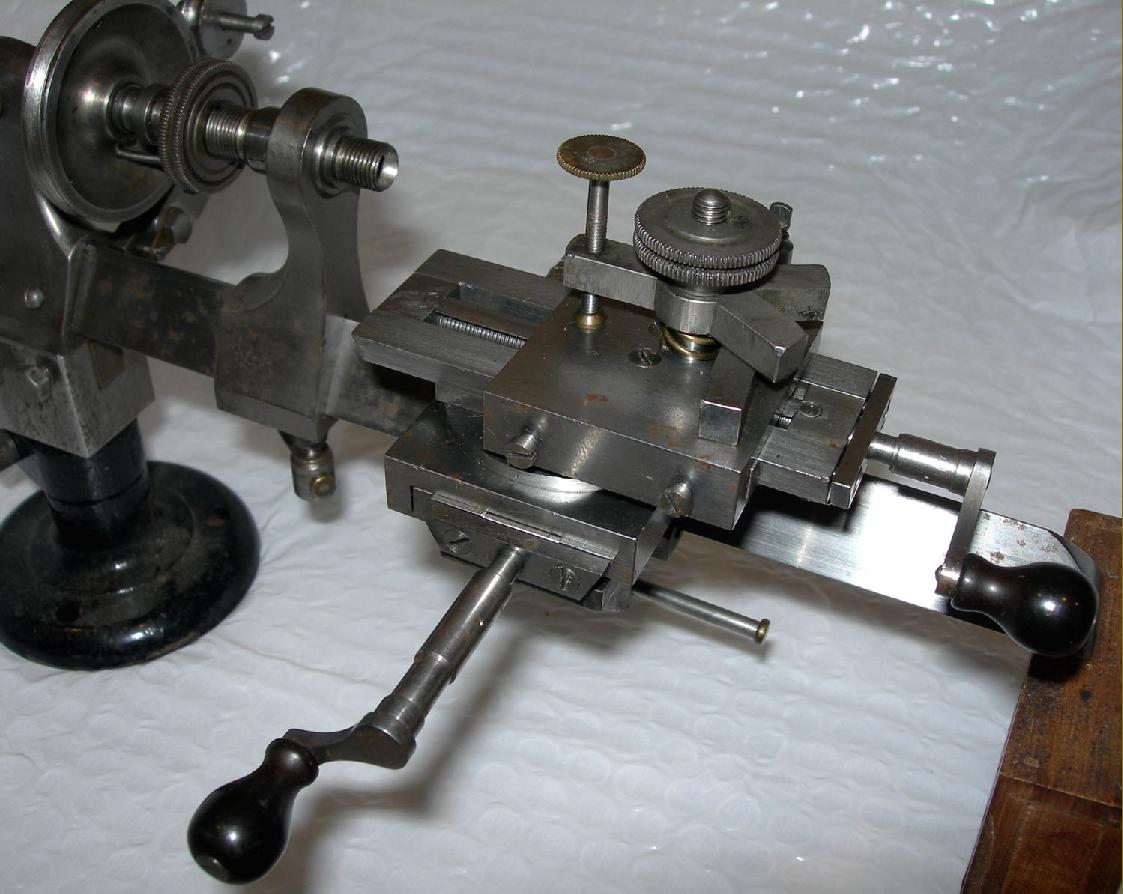

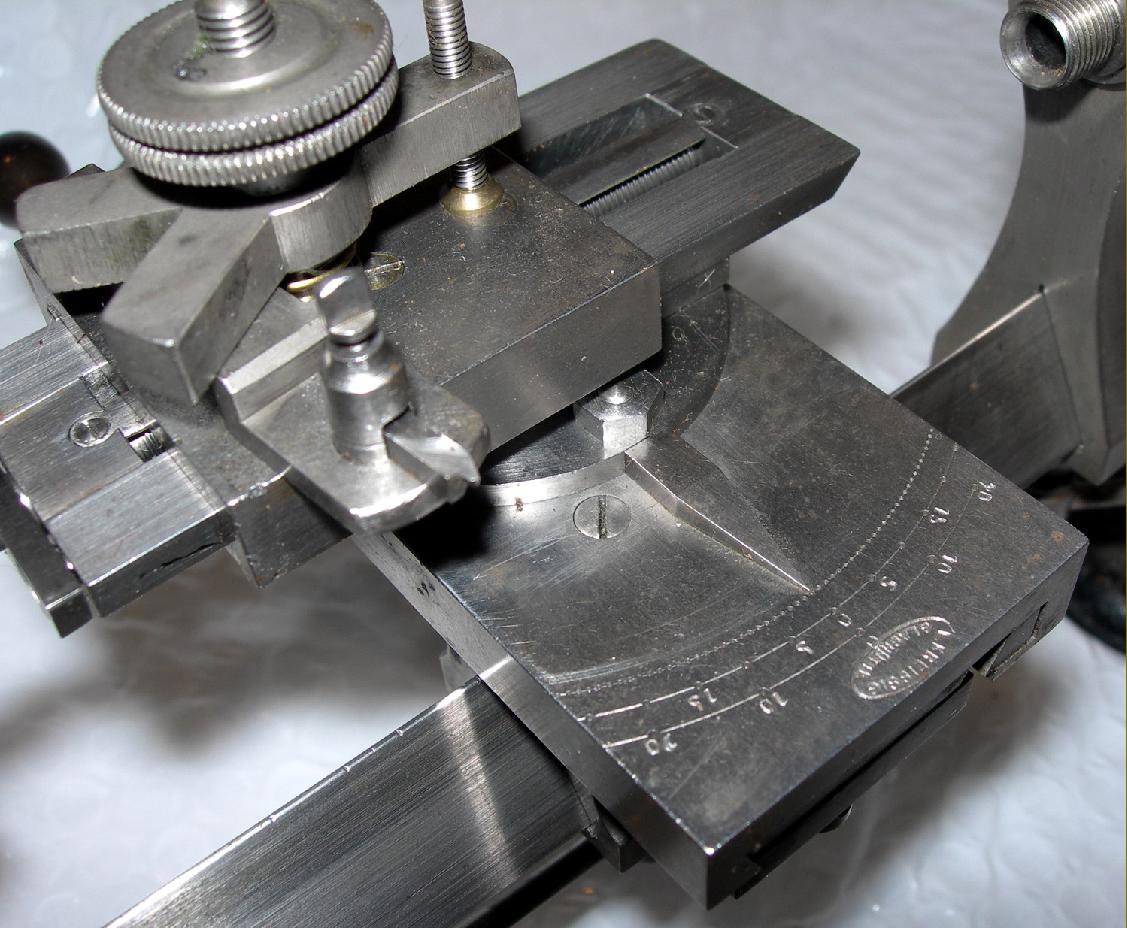

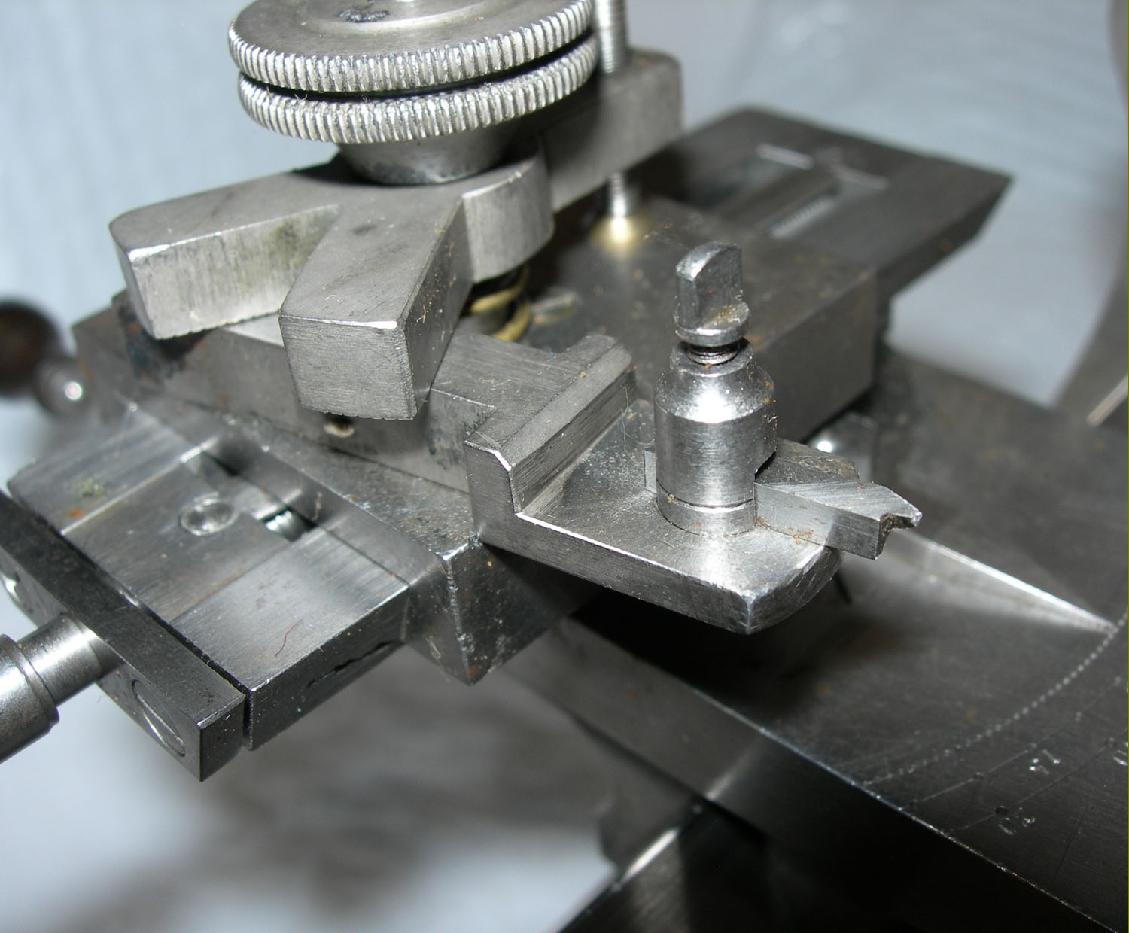

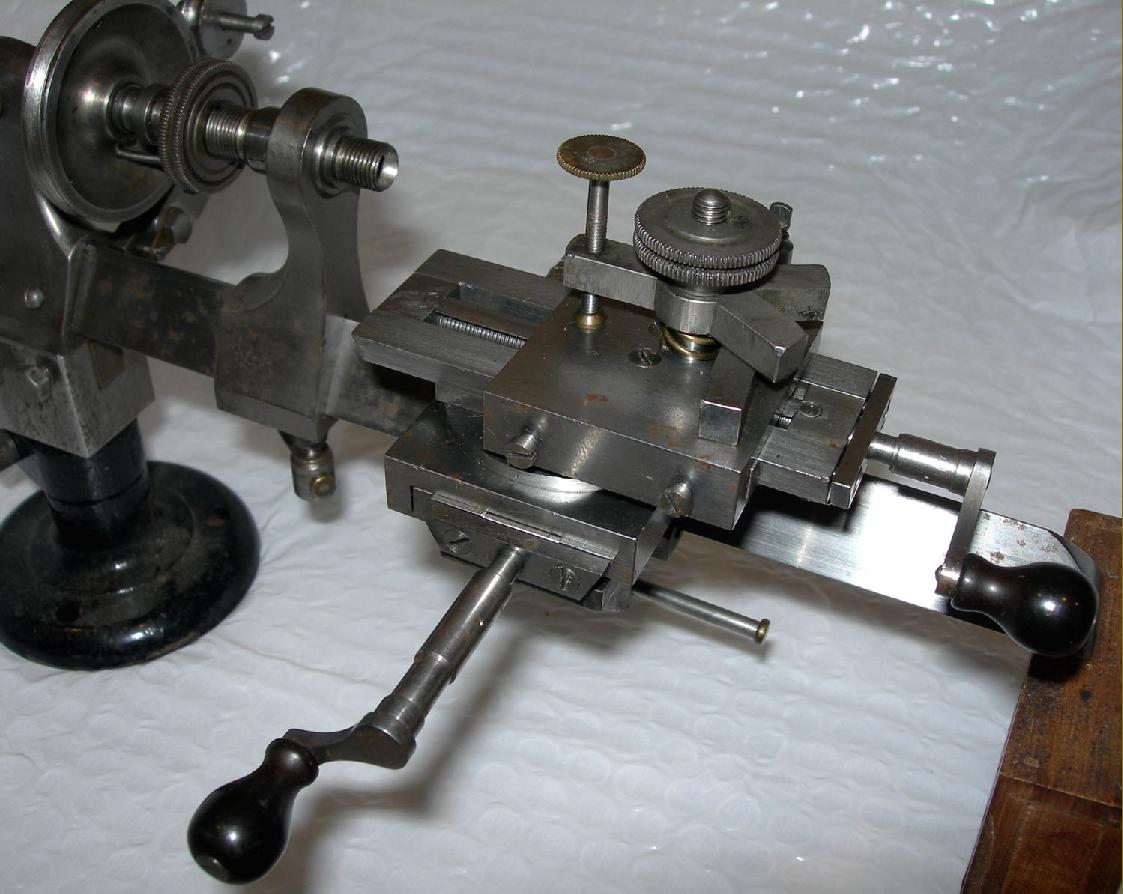

An unusual attachment for the time - and one that was remarkably sophisticated and delicate in operation - was a compound slide rest. Fitted with beautifully-made horn handles this followed customary practice by using ordinary right-hand threads - so giving a "cack-handed" operation where turning the screw "inwards" caused the slide to move "out". The rest of the lathe also reflected early 19th century ideas - with even the fixed steady mimicking those used on larger lathes having a series of different diameter bevelled holes around the periphery of a disc.

The Glashütte is very rare, only one having come to light in recent years. If you have one, the writer would be interested to hear from you..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|  |

|

|

|

|  |

|

|

|

|

|

| Despite 50 years of storage the original finish has suffered little. The shape of headstock and tailstock reflected that of contemporary watchmakers' "turns" |

|

|

|

|

|

|

|  |

|

|

|

|

|  |

|

|

|

| The ingenious arrangement of the two-part headstock assembly showing the drive pulley and the dog-driven spindle. |

|

|

|

|

|

|

|  |

|

|

|

|

|

| Rear view of the headstock showing the adjustable, belt-tensioning jockey pulley |

|

|

|

|

|

|

|  |

|

|

|

|

|

| Visible just in front of the knurled-edge ring is the slot to accept the collet retaining key |

|

|

|

|

|

|

|  |

|

|

|

|

|

| The knurled-edge collet tensioning ring. Note the left-hand thread on the end of the spindle - a fitting used only to hold a stepped-collet compression ring |

|

|

|

|

|

|

|  |

|

|

|

|

|  |

|

|

|

|

|

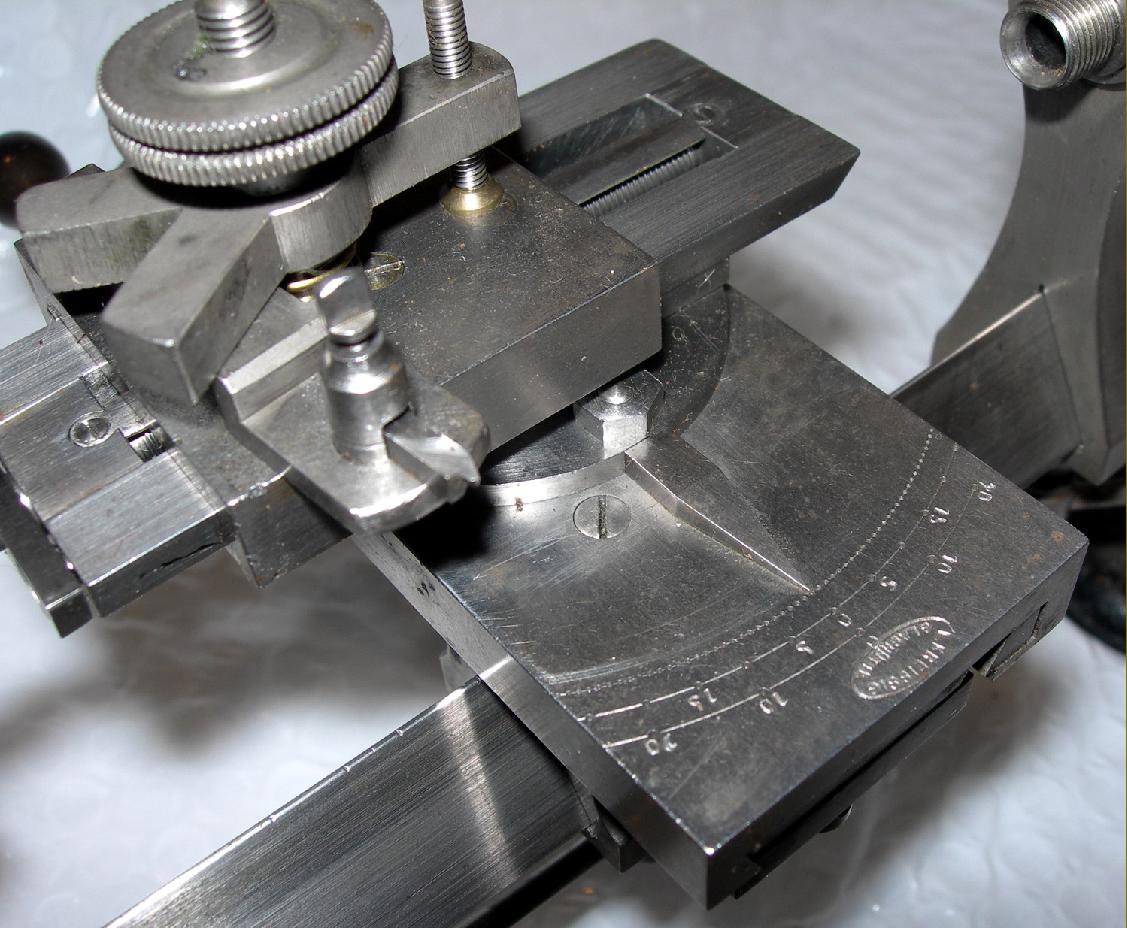

| For its age the compound slide rest, with its horn handles, was remarkably sophisticated and delicate in operation |

|

|

|

|

|

|

|  |

|

|

|

|

|

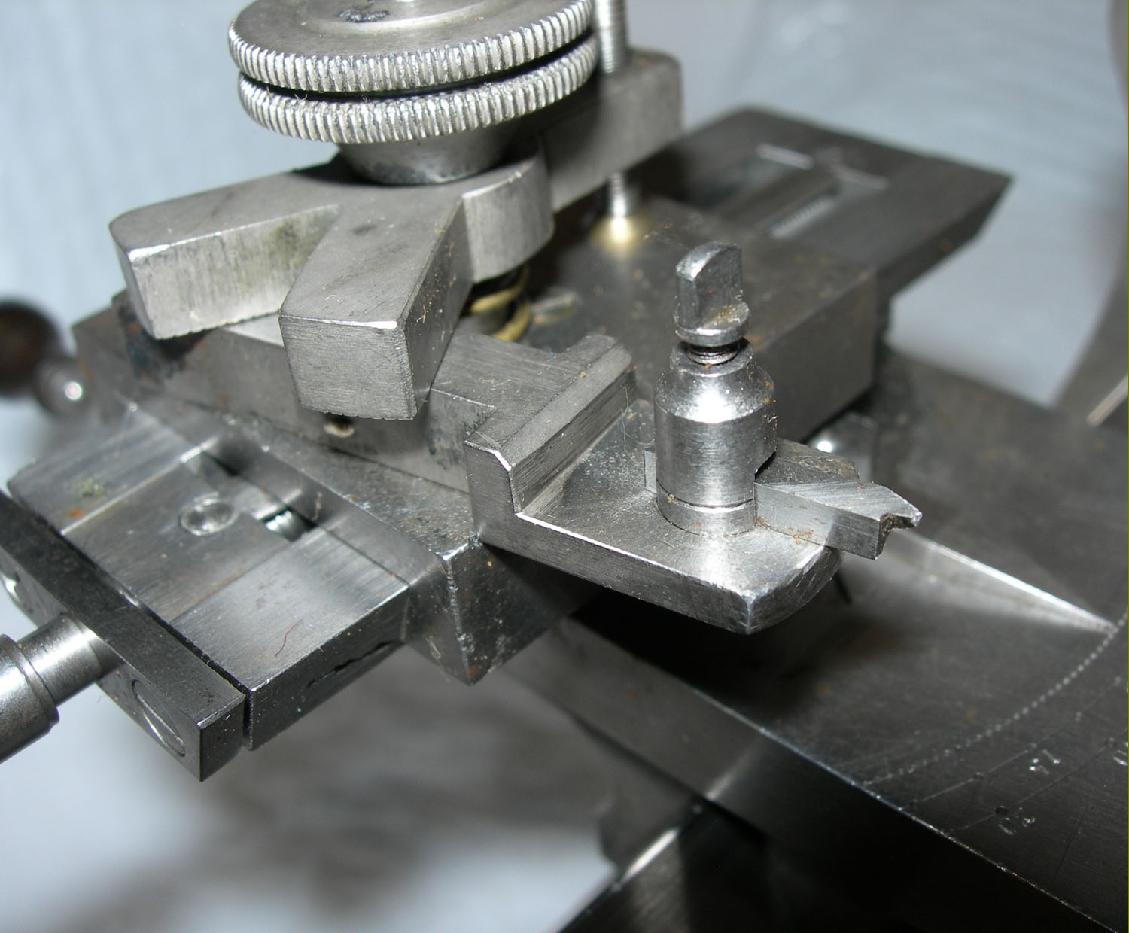

| The superb standard of construction is even more apparent in this picture of the slide removed from the bed |

|

|

|

|

|

|

|  |

|

|

| The compound slide came with its own miniature toolholder |

|

|

|

|

|

|

|  |

Tidak ada komentar:

Posting Komentar